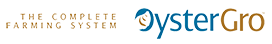

Main cage structure and second layer of crop protection

The OysterGro® bags slide into a user-friendly cage structure, which gives your crop a rugged containment system securing the bags and giving a second layer of protection to your oysters. Accessing your bags is a simple procedure as you unlock the cage door and slide the bags in or out.

The OysterGro® system has two options for you to choose from when it comes to the Main Cage Structure:

Marine Grade Wire Mesh

Since its inception, OysterGro® has delivered secure crop containment that’s manufactured using a high-quality marine grade steel mesh.

Construction:

- High tensile strength premium steel wire

- Wire is hot dip galvanized after welding, leading to a longer lifetime of use that is typically 5-10x more vs. products that are galvanized before welding

- Mesh is then sealed with a high-quality marine grade PVC coating

- Cage structure is reinforced at rope attachment points for added strength

- Assembled with our proprietary high-strength, engineered OG structural clips that are both wider and thicker

- Full bag containment with lockable door secured with our easy-to-use, proprietary Gator lock system

- Available in two build formats – either fully assembled or partially assembled with our “EasyShip” system that allows you to double cage quantities per truck load

Hybrid Shift

For farmers that are working in more aggressive waters, we now offer an option with increased longevity and durability.

We have engineered a hybrid cage system using structural aluminum and rugged polymer composites.

Construction:

- High-grade 6061 aluminum alloy with a T6 temper (30% stronger and 50% harder than T4 temper)

- 3 main interlocking aluminum pieces form the structure of the cage – 2 half-shells (top and bottom) and one shelf (in the middle) that help distribute load and prevent twisting of the cage, especially when raising in the Spring or after a major storm

- 4 interlocking, engineered polymer structural bag dividers

- Fully isolated marine grade hardware

- TIG welded for maximum strength by our in-house Red Seal Certified welding team

- Easy self-assembly using hand tools and supplied hardware

- Full bag containment to prevent loss during storms

- Bag access with our easy-to-use, proprietary Gator lock system

- Grooves on the bottom of the floats to interlock the floats to the cage

- Wider float stance for maximum stability

- Available in two build formats – either fully assembled or partially assembled with our “EasyShip” system that allows you to double cage quantities per truck load

The Hybrid Shift OysterGro® system is our most rugged cage design yet!

Floatation and system rigidity

Attached to each cage is a pair of floats that are connected to the cage structure at multiple points giving not only the floatation needed but also adding rigidity to the system as a whole. With our floats, as with all materials and components that go into OysterGro®, material selection and engineering design is key. This is why our design and polymer formulation, for both our Stealth and Black float range is specifically engineered to deliver rugged performance for your day to day operations.

Precisely engineered because the details matter

All our structural connection components such as OG clips, float retention strands and our braces are unique to OysterGro®. These highly important structural components are specifically designed and manufactured to ensure they meet our exacting engineering standards. If it’s off the shelf, it’s not an OysterGro®.

Tailor made with quality you can trust

In support of your OysterGro® system, we have a wide range of system accessories and operational choices. These options and support materials enable you to tailor the system to meet your needs.